HOW TO DEACTIVATE THE IMMOBILIZER FROM YOUR ECU (COMPLETE GUIDES) UNLOCKING THE SECRET

In today’s automotive world, the immobilizer system plays a crucial role in vehicle security, preventing unauthorized access by disabling the engine unless the correct key is present. However, there are circumstances where deactivating the immobilizer becomes necessary. Whether it's due to a malfunctioning system, lost keys, or modifications such as engine swaps, understanding how to disable this security feature can be essential.

This guide, "How to Deactivate the Immobilizer from Your ECU," is designed to provide a comprehensive look into the process. We will explore the reasons behind immobilizer deactivation, the technical steps involved, and the potential risks and legal considerations that come with it. This guide is intended for those with a strong background in automotive electronics, as the task requires precision and expertise.

Deactivating an immobilizer is not a decision to be made lightly, and this guide aims to equip you with the knowledge needed to approach this process responsibly and effectively. Whether you’re a professional technician or an advanced DIYer, this guide will serve as your roadmap to safely and successfully navigating the complexities of immobilizer deactivation.

WHAT IS THE IMMOBILIZER SYSTEM AND WHY IS IT IMPORTANT?

The immobilizer system is a security feature that prevents your car from starting without the right key. The key has a small chip inside that sends a code to the ECU when you insert it in the ignition. The ECU checks the code and if it matches, it allows the engine to start. If the code does not match, the ECU blocks the engine and the car will not start.

The immobilizer system is important because it protects your car from theft. Without the right key, no one can start your car, even if they break into it or hotwire it. The immobilizer system also helps your car run better and save fuel, by adjusting the air-fuel ratio and the ignition timing according to the oxygen level in the exhaust gas.

The immobilizer system is usually installed in the factory, but some car owners may choose to add it later.

THERE ARE DIFFERENT TYPES OF IMMOBILIZER SYSTEMS, SUCH AS:

(1): PASSIVE IMMOBILIZER:

This type of immobilizer activates automatically when you turn off the ignition. You do not need to do anything else to activate it.

(2): ACTIVE IMMOBILIZER:

This type of immobilizer requires you to press a button or use a remote control to activate it. You need to do this every time you park your car.

(3): SMART KEY IMMOBILIZER:

This type of immobilizer uses a smart key that you can keep in your pocket or purse. The car will recognize the smart key when you are near it and will unlock the doors and start the engine automatically.

HOW TO DEACTIVATE THE IMMOBILIZER FROM YOUR ECU?

There are many reasons why you may want to deactivate the immobilizer from your ECU. For example, you may want to:

Troubleshoot some engine problems that may be caused by the immobilizer system.

Install some aftermarket parts that may not be compatible with the immobilizer system.

Perform an engine swap that may require a different ECU or key.

Whatever your reason, there are different methods to deactivate the immobilizer from your ECU. Here are some of them:

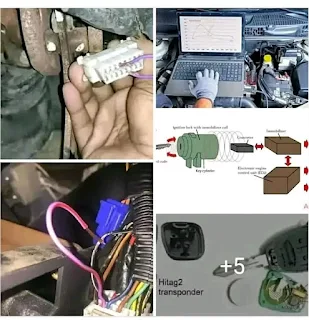

SOFTWARE REPRORAMMING

This method involves using specialized software and hardware to modify the ECU’s program and disable the immobilizer function. You will need a laptop, a cable, and a software program that can read and write the ECU’s data. You will also need to know the password or the security code of your ECU, which may be different for each car model and year.

TO USE THIS METHOD, YOUR WILL NEED to:

✔️-Connect the laptop to the ECU using the cable.

✔️-Run the software program and select the option to read the ECU’s data.

✔️-Save the data as a backup file in case something goes wrong.

✔️-Find the immobilizer function in the data and change its value to zero or off.

✔️-Select the option to write the new data to the ECU.

✔️-Disconnect the laptop and the cable and test the car.

THE PROS OF THIS METHOD ARE:

✔️it is relatively cheap and easy to do, if you have the right tools and knowledge.

✔️-It does not require any physical modification of the car or the ECU.

✔️-It can be reversed by restoring the original data to the ECU.

THE CONS OF THIS METHOD ARE:

It can damage the ECU or the car if you make a mistake or use the wrong software or cable.

It can void your warranty and make your car fail an emissions test.

It can make your car more vulnerable to theft, as anyone can start it without the key.

IMMOBILIZER BYPASS MODULE

This method involves installing a bypass module that intercepts the communication between the immobilizer and the ECU, effectively tricking the system into thinking the key is present. You will need a bypass module that is compatible with your car model and year, and some basic tools to install it.

TO USE THIS METHOD, YOU WILL NEED TO:

✔️-Locate the immobilizer system in your car, which is usually near the ignition switch or the steering column.

✔️-Disconnect the wires that connect the immobilizer to the ECU.

✔️-Connect the bypass module to the wires, ✔️-following the instructions of the module manufacturer.

✔️-Test the car and make sure it starts without the key.

THE PROS OF THIS METHOD ARE

-It is relatively simple and quick to do, if you have the right module and tools.

-It does not require any modification of the ECU or the car’s program.

-It can be removed easily if you want to restore the immobilizer function.

THE CONS OF THIS METHOD ARE:

✔️-It can be expensive and hard to find a suitable bypass module for your car.

✔️-It can cause some electrical or compatibility issues with the car or the ECU.

✔️-It can void your warranty and make your car fail an emissions test.

✔️-It can make your car more vulnerable to theft, as anyone can start it without the key.

PHYSICAL MODIFICATION

This method involves physically modifying the immobilizer system itself, such as removing or bypassing certain components. You will need some tools, such as a screwdriver, a wire cutter, and a soldering iron, and some skills, such as wiring and soldering

TO USE THIS METHOD, YOU WILL NEED TO:

✔️-Locate the immobilizer system in your car, which is usually near the ignition switch or the steering column.

✔️-Identify the components that are responsible for the immobilizer function, such as the antenna, the transponder, or the relay.

✔️-Remove or bypass the components, depending on the type of immobilizer system you have. For example, you may need to:

✔️- Cut the wire that connects the antenna to the ECU and solder a resistor to it.

✔️-Remove the transponder from the key and glue it near the ignition switch.

✔️- Bypass the relay that controls the fuel pump or the starter motor.

✔️&Test the car and make sure it starts without the key.

THE PROS OF THIS METHOD ARE:

✔️-It is cheap and easy to do, if you have the right tools and skills.

✔️-It does not require any software or hardware to modify the ECU or the car’s program.

✔️-It can be reversed by restoring the original components to the immobilizer system.

THE CONS OF THIS METHOD ARE:

✔️-It can damage the immobilizer system or the car if you make a mistake or use the wrong tools or components.

✔️-It can void your warranty and make your car fail an emissions test.

✔️-It can make your car more vulnerable to theft, as anyone can start it without the key.

WHAT ARE THE LEGAL IMPLICATIONS OF DEACTIVATING THE IMMOBILIZER?

Before you decide to deactivate the immobilizer from your ECU, you need to consider the legal implications of doing so. Depending on where you live, deactivating the immobilizer may be illegal or restricted by law. This is because the immobilizer system is considered a safety and environmental feature that helps prevent car theft and reduce emissions.

IF YOU DEACTIVATE THE IMMOBILIZER, YOU MAY FACE SOME LEGAL CONSEQUENCES, SUCH AS:

✔️-Fines or penalties for tampering with a vehicle’s safety or emission systems.

✔️-Loss of insurance coverage or increased premiums for modifying your car without notifying your insurer.

✔️-Rejection of warranty claims or service contracts for altering your car’s original condition.

✔️-Failure of inspection or registration tests for not meeting the minimum safety or emission standards.

Therefore, before you deactivate the immobilizer, you should check the laws and regulations of your country, state, or region. You should also consult with your insurer, your dealer, or your mechanic to find out how deactivating the immobilizer will affect your car’s warranty, insurance, and service.

WHAT ARE THE ALTERNATIVES TO DEACTIVATING THE IMMOBILIZER?

If you are having some issues with your car that make you want to deactivate the immobilizer, you may want to consider some alternatives before you do so. Deactivating the immobilizer is not the only solution to your problems, and it may not be the best one. Here are some alternatives that you may want to try:

Replacing the key fob or ignition switch: If your key fob or ignition switch is damaged or worn out, it may not send the right code to the ECU, causing the immobilizer to block the engine. You can replace the key fob or ignition switch with a new one that matches your car’s code. You can buy a new key fob or ignition switch from your dealer or online, and program it yourself.

REPRORAMMING THE IMMOBILIZER SYSTEM:

If you have changed your ECU or key, or if your immobilizer system has been corrupted or reset, you may need to reprogram the immobilizer system to match your car’s code. You can reprogram the immobilizer system with the help of a qualified technician, who can use a diagnostic tool to access the ECU and the immobilizer system and synchronize them. You may also need to provide some proof of ownership and identification to verify that you are the legitimate owner of the car.

INVESTING IN A SECONDARY IMMOBILIZER SYSTEM:

If you want to enhance the security of your car, you may want to invest in a secondary immobilizer system that adds another layer of protection to your car. A secondary immobilizer system can be a steering wheel lock, a brake pedal lock, a kill switch, or a GPS tracker. These devices can deter or prevent thieves from stealing your car, or help you recover your car if it is stolen.

IN CONCLUSION:

Deactivating the immobilizer from your ECU is a complex process that requires a deep understanding of automotive electronics, programming, and vehicle security systems. Immobilizers are designed to prevent unauthorized access to your vehicle by disabling the engine unless the correct key or key fob is used. While deactivation might be necessary in certain situations—such as when dealing with lost keys, faulty immobilizer systems, or engine swaps—it's a procedure that should be approached with caution and respect for the legal and ethical implications.

The complete guides provided herein have outlined the step-by-step procedures involved in disabling the immobilizer system. This includes gaining access to the ECU, understanding and modifying the relevant software or hardware, and ensuring that the vehicle remains operational and secure after the deactivation. It's important to note that these guides are intended for professional use and should only be undertaken by individuals with the necessary skills and experience.

Professionals in the automotive industry often encounter situations where immobilizer deactivation is required. Whether for diagnostic purposes, repairs, or customization, understanding how to safely and effectively deactivate the immobilizer can be a valuable skill. However, it's crucial to be aware of the potential risks, including the possibility of making the vehicle more vulnerable to theft or causing unintended damage to the ECU or other electronic components.

Furthermore, one must consider the legal implications of such actions. Immobilizer systems are a key part of a vehicle's security, and tampering with them can have legal consequences, especially if the vehicle is later involved in criminal activity. Always ensure that any modifications made to a vehicle's security system comply with local laws and regulations.

While the process of deactivating an immobilizer from your ECU can unlock new possibilities for vehicle customization and repair, it should be performed with the utmost care and responsibility. The information provided in this guide serves as a comprehensive resource for those with the expertise to undertake such a task, but it should never be used to circumvent vehicle security for unauthorized purposes. As with any advanced automotive procedure, when in doubt, consult with a professional or specialist to ensure that the process is carried out correctly and safely